| |

|||||||||

| |

|

|

|

|

|

|

|

||

| Home | About | Literature | Site Map | MSDS | Contact | Engineers | Shows | Links | Samples | RFQ | Catalog Numbers |

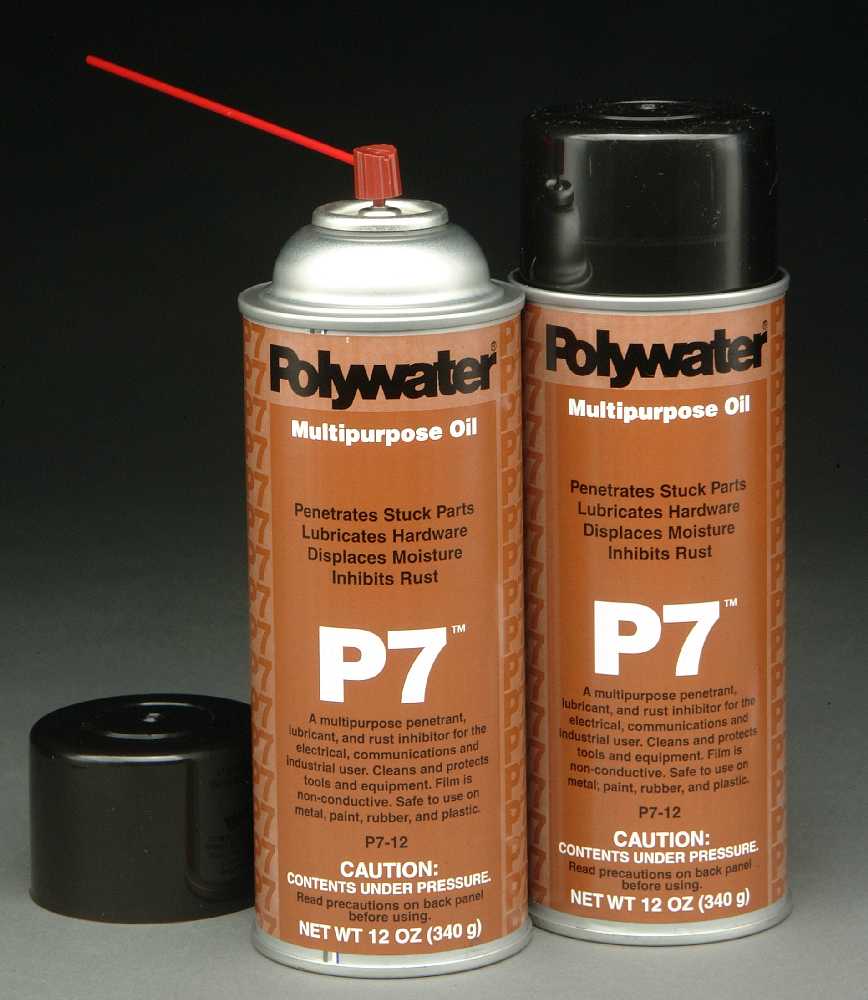

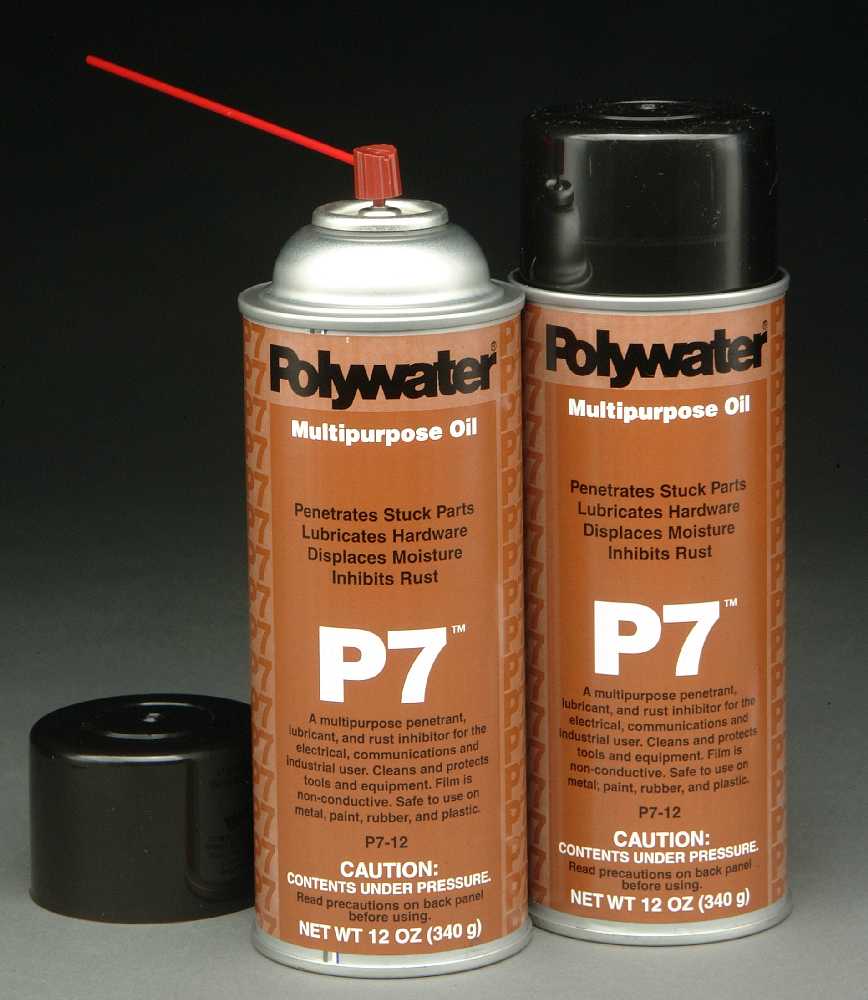

| Multipurpose! P7™ A Multi-Functional |

|

P7™ Penetrating Oil is suitable for all kinds of electrical and industrial uses. P7™ Oil cleans dirt and grime, loosens rust and scale, and penetrates frozen parts. Use it to maintain and lubricate equipment.

P7™ Penetrating Oil is multi-functional. It cleans, penetrates, and lubricates to extend equipment life. P7™ Oil also acts as a moisture displacer and corrosion inhibitor. It drives out moisture and dries wet connections, leaving a protective film that is non-conductive.

|

|

|

|

Flashpoint (ASTM D93) Initial Boiling Point Specific Gravity Dielectric Strength (ASTM D877) Relative Evaporation Rate Propellant USDA |

100°F/38°C 245°F/118°C 0.69 13 KV Fast Hydrocarbon Approved |

P7™ Penetrating Oil cleans grease and tars and removes adhesives and rust. Other solvent cleaners are not necessary. P7™ Oil dissolves grit and grime contaminants, leaving behind a fine protective film.

P7™ Penetrating Oil has a low surface tension, which allows it to spread into a very fine film. One 12-ounce can of P7™ Oil will cover approximately 300 square feet of surface. This low surface tension allows P7™ Oil to "creep" up surfaces against gravity. It will penetrate and coat 16mm of a threaded bolt in 15 minutes. P7™ Oil will lubricate tight crevices and loosen frozen parts.

P7™ Penetrating Oil offers superior corrosion protection by leaving a non-conductive film. This long-lasting film increases service life.

The photo at right shows the results of a three-week outdoor weathering test run on low carbon steel. The plates were sanded, cleaned, and saturated with various penetrating oils. The steel plates were left in the elements, untouched for three weeks. P7™ acts as a tough, protective barrier; the steel plate has no rusting or mottling at the conclusion of the test.

P7™ Penetrating Oil is an exceptional lubricant. The coefficient of friction can be determined using the Falex Pin and Vee Block Test Machine (ASTM D3233A). Load is applied to two V-blocks that press against a rotating steel journal immersed in the oil. The coefficient of friction value is derived from the torque measurement on the pin. The more the penetrating oil lubricates and lowers the torque, the lower the resulting coefficient of friction. Documented test results show that P7™ Oil has a significantly lower coefficient of friction than other commonly used penetrating oils.

Extreme pressure testing using the Pin and Vee Block Test Machine confirms P7™ Oil's excellent performance under high loads. The test will run to a load force of over 1,000 pounds before failure.

P7™ Penetrating Oil displaces moisture and dries out ignitions. It creeps under water and ice, dissolving and carrying away these contaminants. A non-conductive, protective film is left behind. P7™ Oil displaces water according to the procedure described in Mil-Spec C-16173E. No rusting or mottling was observed on the treated surface.

P7™ Penetrating Oil is compatible with most plastics and elastomers. Tables I and II show the effect of P7™ Oil on various plastics and rubbers.

Testing is based on a soak test described in ASTM D543. P7™ Oil will temporarily affect some rubber compounds. These rubbers may swell, but should return to their original state after the solvent carrier has dried. Immersion will affect sensitive materials more than incidental contact of a spray and wipe. It is recommended that all plastic parts, gaskets, seals and O-rings be tested for specific use and exposure method.

| AGING 72 HOURS AT 50°C | ||||

|---|---|---|---|---|

| TYPE OF PLASTIC | % WEIGHT CHANGE | % THICKNESS CHANGE | APPEARANCE | |

| ABS | +0.04 | +0.79 | NC | |

| Acrylic | -0.02 | -0.04 | NC | |

| CPE Thermoplastic | +16.10 | +4.27 | NC | |

| CPE Thermoset | +22.12 | +20.99 | SS | |

| Delrin® | +0.17 | +0.25 | NC | |

| Epoxy | -0.05 | 0 | NC | |

| Nylon 101 | -0.08 | -1.57 | NC | |

| Polycarbonate | -0.03 | -0.59 | NC | |

| Phenolic | +1.24 | 0 | NC | |

| Polyethylene | +14.19 | +5.44 | NC | |

| Polystyrene | +13.85 | -3.64 | SF | |

| PVC | +0.06 | 0 | NC | |

| Teflon® | +0.07 | -0.25 | NC | |

| Tygon® | +4.95 | 0 | NC | |

| Ultem® 1000 | -0.08 | -0.27 | NC | |

| Valox® 420 | +0.03 | -1.11 | NC | |

| AGING 72 HOURS AT 50°C | ||||

|---|---|---|---|---|

| TYPE OF ELASTOMER | % WEIGHT CHANGE | % THICKNESS CHANGE | APPEARANCE | |

| EPDM | +149.56 | +43.77 | S | |

| Neoprene | +26.64 | +9.79 | SS | |

| Nitrile | +1.06 | 0 | NC | |

| SBR | +52.48 | +14.36 | S | |

| Silicone | +48.04 | +17.87 | S | |

| Viton® | +0.56 | +0.26 | NC | |

KEY: NC=NO CHANGE Type P7™ is a trademark of American Polywater Corporation

SF=SOFTENING Delrin® and Teflon® are trademarks of Du Pont

SS=SLIGHT SWELLING Ultem® 1000 and Valox® 420 are trademarks of G.E. Plastics

S=SWELLING Tygon® is a trademark of Norton Performance Plastics

Viton® is a trademark of Du Pont Dow Elastomers

Position nozzle 6 to 8 inches (15-20 cms) from surface and spray with light even strokes. Use extension tube for difficult to reach areas. Let P7™ Oil soak for several minutes to loosen rusted parts. Allow 4 to 6 hours to fully dry. P7™ Oil eaves a non-conductive, protective film.

P7™ Penetrating Oil has a low level of toxicity. Avoid breathing spray, mist, or vapor. As with any solvent, ventilation should be sufficient to keep vapors at safe levels.

P7™ Penetrating Oil is combustible. Do not expose to fire or flame. Good industrial hygiene practice and appropriate precautions should be employed during use.

P7™ Penetrating Oil is classified as combustible. Keep containers cool, dry and away from sources of ignition and oxidizing materials. Do not expose aerosol cans to direct sunlight or temperatures above 120°F (50°C). Do not puncture or incinerate aerosol cans. Aerosol cans are freeze/thaw stable. This product has a shelf life of three years.

| CATALOG NUMBERS | |||

|---|---|---|---|

| Type P7™ | Package Size | Units/CS | Image |

| P7-12 | 16 fluid oz (475 ml) aerosol can. Net wt 10 oz. | 12 |  |

Click here for an MSDS on this product

Click here to Request a Quote on this product

Click here to Add Your Name To Our Mail List

View this flyer in Spanish or in Chinese or in PDF Format

Important Notice: The statements and information here are made in good faith based on tests and observations we believe to be reliable. However, the completeness and accuracy of the information is not guaranteed. Before using, the end-user should conduct whatever evaluations are necessary to determine that the product is suitable for the intended use. The user assumes all risks and liability in connection with such use. The statements contained herein are made in lieu of all warranties, express or implied, including, but not limited to, implied warranties of merchantability and fitness for a particular purpose, which warranties are hereby expressly disclaimed. American Polywater's only obligation shall be to replace such quantity of the product proven to be defective. Except for the replacement remedy, American Polywater shall not be liable for any loss, injury or damage, direct or indirect, arising from the use or the failure to properly use these products, regardless of the legal theory asserted. The foregoing may not be altered except by a written agreement by the officers of American Polywater Corporation.

Ask for Polywater® products by name at your local authorized distributor

Home |

About |

Site Map |

Literature |

Samples |

Links |

Reps |

Videos |

Pumps |

RFQ

Codes |

Engineering |

Shows |

Spotlight |

Newsletters |

MSDS |

Translations |

Contacts |

Jobs

11222 60th ST N | Stillwater, MN 55082-9310 USA

1-(651) 430-2270 (Voice) | 1-(651) 430-3634 (Fax)

1-(800) 328-9384 (Toll-Free US/Canada Only)

Copyright © 2001 - 2015 American Polywater Corporation | ![]() 6/5/15

6/5/15