| Home | Products | Representatives | Resources | SDS | Contact |

| Polywater Support Page |

|

LSZH & CSPE Compatible

Polywater® LZCable Pulling LubricantSpecification-Grade Lubricant for Pulling Low Smoke Zero Halogen Cables (LSZH and LSHF) |

| |

Polywater® LZ is the only pulling lubricant developed for and tested on LSZH/LSHF jackets. It meets the performance needs of power plants, mass transit systems, airports, petrochemicals, high-occupancy buildings, and other construction projects using LSZH power, control, instrumentation, and communication cables. Polywater® LZ is a specification-grade, clean, slow-drying, gel lubricant that is broadly compatible with low-smoke zero-halogen jackets. Lubricant LZ provides reduced tension on all types of cable jackets. Lubricant LZ dries to a thin lubricating film that retains its lubricity for months and won’t cement in the cables. Polywater® LZ is also tested and broadly compatible with CSPE (chlorosulfonated polyethylene) fire-retardant cable jackets. Polywater Lubricant LZ is the recommended lubricant choice for all CSPE cable installations. Research on Cable Pulling Lubricant Fire Parameters: An International Wire & Cable Symposium paper entitled “Fire Parameters and Combustion Properties of Cable Pulling Compound Residues“ presents startling data on lubricant residue combustibility. In the research, “wax-type“ lubricants were found to melt, ignite easily, burn vigorously, and spread flame through a conduit. This paper with details on energy flux testing is available online at www.polywater.com/IWCS.html. Cable Compatibility: Cable pulling lubricant compatibility is evaluated using IEEE 1210 test methods. Tensile strength and elongation tests were performed on over 29 different LSZH cable jackets representing a number of manufacturers and LSZH technologies. Cable jackets were aged in the lubricant at the temperatures specified in the standard. Polywater® LZ lubricant showed the broadest compatibility with LSZH cable jackets. Most cable pulling lubricants available through local supply houses had significant and sometimes devastating effects on LSZH cable jackets. Shown at lower right is a photograph where improper cable lubricant choice contributed to LSZH cable jacket failure. Recommendations: Engineers should specify a cable pulling lubricant that does not negate the fire suppression effectiveness of fire-retardant cables or degrade jacket materials. Performance specifications for lubricants should include physical property effects, jacket compatibility, ignition and flame propagation character of residues, coefficient of friction parameters specific to cable type, and manufacturer approvals. Polywater® LZ offers proven cable compatibility, superior combustion resistance, and an inherently low coefficient of friction. Polywater® LZ should be specified for installations of LSZH/LSHF cable in duct. Caution: Because of ongoing production and formulation advances in LSZH cable technology, please verify with cable manufacturers the current status of lubricant compatibility, or contact American Polywater directly for specific jacket details. |

Wax-based lubes destroyed some low-smoke zero-halogen cable jackets in aging tests. |

| |

Lubricant residue from an adjacent duct system contributed to LSZH jacket failure. | |

|

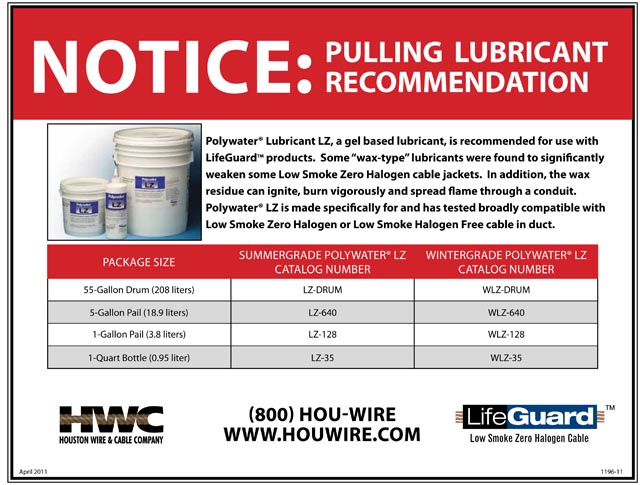

Houston Wire & Cable now applies this pulling lubricant recommendation to every reel of their LifeGuard™ LSZH cable |

UL and ULc Listed

View a Technical Data Sheet on LZ

Voir une Fiche Technique pour LZ

Click here for an MSDS on this product

View our other Lubricant Selection Guide

View flyer in PDF or Franšais, Spanish or Chinese

Click here to Add Your Name To Our Mail List

Click here to Request a Quote on This Product

Click for an approval from The Okonite Company

View a PowerPoint on LSZH Cable Failure Research

Click for a recommendation from Houston Wire & Cable and RSCC Wire & Cable

Important Notice: The statements and information here are made in good faith based on tests and observations we believe to be reliable. However, the completeness and accuracy of the information is not guaranteed. Before using, the end-user should conduct whatever evaluations are necessary to determine that the product is suitable for the intended use. The user assumes all risks and liability in connection with such use. The statements contained herein are made in lieu of all warranties, express or implied, including, but not limited to, implied warranties of merchantability and fitness for a particular purpose, which warranties are hereby expressly disclaimed. American Polywater's only obligation shall be to replace such quantity of the product proven to be defective. Except for the replacement remedy, American Polywater shall not be liable for any loss, injury or damage, direct or indirect, arising from the use or the failure to properly use these products, regardless of the legal theory asserted. The foregoing may not be altered except by a written agreement by the officers of American Polywater Corporation.

This website uses third party cookies to analyze navigation and to improve the quality of the user experience. Address: 11222 60th Street N, Stillwater, MN 55082, USA Phone: +1 651 430-2270 | Fax: +1 651 430-3634 | Phone: 800 328-9384 (Toll-Free USA/Canada) General Email: Email Contact Page |